IN celebrating its 150th anniversary, Milan-based tyre company PIRELLI has displayed its ability to roll with the times.

IN celebrating its 150th anniversary, Milan-based tyre company PIRELLI has displayed its ability to roll with the times.

Since it hit the road in 1872, the brand has gained momentum, spreading its reach around the globe, showing a willingness to move with the changes that have kicked in as a result of the industrial and technological revolutions.

It has been a journey with many twists and turns, not always smooth, but one that the sixth-largest tyre manufacturer has navigated confidently, remaining a much sought-after brand for cars, motorcycles and bicycles.

In 2015, China National Chemical Corp Ltd took controlling interest of PIRELLI. PIRELLI has been listed on the Milan Stock Exchange since 1922, and operates in over 160 countries, manufacturing in 13 of them.

Fabio Lopes (pictured top), the Managing Director of PIRELLI Asia, talks to STORM-ASIA about the brand’s road ahead.

STORM-ASIA: How does a heritage brand remain relevant to the times?

FABIO LOPES: As we celebrate our 150th birthday this year and look back at the significant milestones and achievements, PIRELLI is indeed a powerful brand beyond tyres. It is the passion for innovation that drives the brand forward and ensures that we stay ahead of trends.

Represented by the unmistakable ‘long P’ logo for more than a century, the PIRELLI name is associated with exclusivity, luxury, and innovation, strengthening its distinctive position as a supplier to luxury car manufacturers. Moreover, PIRELLI continually enhances the reputation and strength of the brand through its involvement in motorsport events and competitions, cultural and artistic projects and initiatives benefiting local communities.

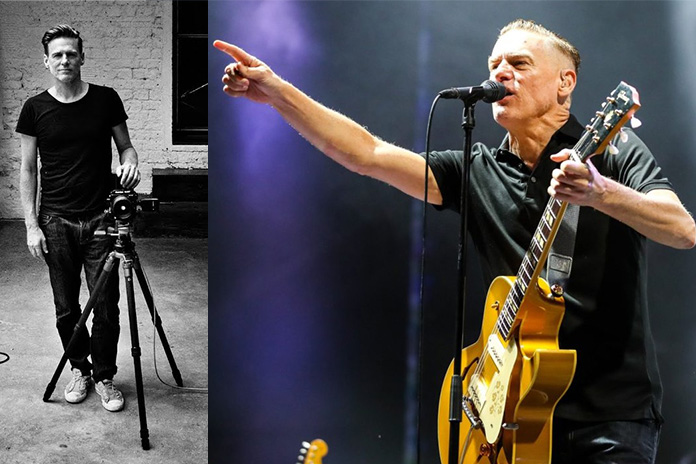

PIRELLI has always been at the forefront in terms of culture and style through its highly coveted PIRELLI Calendar projects. 2022’s music-themed Calendar was shot by rock star and photographer Bryan Adams, featuring superstars Cher, Jennifer Hudson and Iggy Pop. Next year’s calendar will be its 49th edition, where Emma Summerton, the London and New-York-based photographer known for her distinctive style and dramatic Vogue magazine covers, will bring her signature vision to it.

On the design side, PIRELLI works with numerous partners including Montblanc, Roger Dubuis and Blossom — each one a company of excellence in its field. These partnerships have led to the launch of pens and trolley cases, watches and skis which, thanks to the know-how and technology of PIRELLI, boast even more sophisticated features.

In Southeast Asia, the COVID-19 pandemic has accelerated the growth of e-commerce and we are among the first premium tyre brands in the region to set up an official flagship store on online platform Lazada in Thailand, Malaysia, Philippines and Singapore. This strategic move not only opened up a new commercial channel for PIRELLI, but our customers in the region are also able to enjoy greater convenience and accessibility to our car tyres.

STORM-ASIA: What have been the benefits of the Formula One association?

FABIO LOPES: Motorsport is PIRELLI’s biggest open-air research and development laboratory, designed to push tyres to extremes of performance on some of the most challenging roads of the world, in all sorts of weather conditions.

PIRELLI has been the Global Tyre Partner of F1 since 2011 and the strong presence in motorsport enables us to generate avant-garde solutions that are then transferred to tyre ranges for the consumer market, ensuring the maximum levels of performance and safety.

With the move from 13 to 18 inches in F1 tyres since this year, it adds vital relevance to the tyres that we use every day on the road. Over the years, tyres have got progressively bigger. So 18 inches is now a relatively common size for performance vehicles, meaning that F1’s move to these dimensions is more useful in helping PIRELLI to develop tyres that will ultimately be used on the road. It’s not just the actual 18-inch tyre technology that’s transferred from track to road, but also the design and production processes used to make them.

The result — more performance and control, both on the road and the track.

Proof of the close links between racing and real-world driving can be found on the sides of the tyres themselves: the names P Zero and Cinturato, as seen in F1, are also the names of PIRELLI’s Ultra High Performance tyres for everyday motorists.

In addition, the expertise generated in motorsport, like the Virtual Simulation Technology, has expanded its benefits to our road tyres. Similarly, in the development of the Cinturato Rosso, the performance goals of the product were achieved faster with less physical prototypes needed, all thanks to data analysis from the static simulator and virtual models. This consequently benefits the environment as per PIRELLI’s sustainability ethos, from raw materials to development to product to end of tyre life.

STORM-ASIA: Will electric vehicles result in new tyre compounds and tread patterns?

FABIO LOPES: PIRELLI has in place a series of research and development collaborations and joint development agreements with external players such as suppliers, universities and car manufacturers in innovative technologies.

One of the results from the R&D collaborations with premium car manufacturers is the development of Elect tyres engineered specifically for electric and hybrid cars, in order to capitalise on the car’s performance, with a specific compound, construction and tread pattern design.

The development of Elect tyres took into consideration these four characteristics.

Low consumption

The rolling resistance of electric vehicle tyres must be as low as possible, in order to ensure the lowest energy consumption. PIRELLI tyres with Elect technology optimise battery life thanks to their low rolling resistance.

Instant torque

Compared to conventional internal combustion engines, electric vehicles transmit immediate torque to the wheels. To transfer this power onto the tyres without excessive wear, Elect tyres have a specific compound that delivers immediate grip. There are more than 250 PIRELLI Elect™ tyres approved for electric or plug-in hybrid vehicles worldwide by main car manufacturers in the last year.

Weight

The weight of the batteries means that electric vehicles have a unique vertical weight distribution. This places considerable stresses on the tyres during all phases of driving. Elect tyres are specially developed to support this weight thanks to an optimal combination of materials, layout, and design and correct deformation of the structure enhancing the control of the performance of the vehicle.

Noise

Electric vehicles are silent. So the tyres have to complement this attribute to enhance driving comfort. Elect tyres have an optimised tread pattern and structure design to minimise noise when driving.

STORM-ASIA: How many tyres does PIRELLI produce annually?

FABIO MARCOLA LOPES: PIRELLI has 73 million car tyres capacity per year and 71% of the total capacity are from high-value tyres. Over the years, PIRELLI has concentrated, above all, on the development, production and marketing of tyres with large rim sizes, special technical and aesthetic characteristics while being associated with high performance, advanced technology and safety.

We have observed a steady rise of the premium market and thanks to the strong partnership with prestige and premium automotive manufacturers globally, we also see a growing demand for PIRELLI tyres through the original equipment channel.

PIRELLI engineers work very closely with the world’s most prestigious car manufacturers since the homologation process begins at the start of the tyre development stage, which is usually three to five years before the car is officially launched to the markets. As such, PIRELLI has always been able to stay ahead of trends and latest technology.

STORM-ASIA: What is the Asian appetite for PIRELLI tyres?

FABIO LOPES: With reference to car ownership in Southeast Asia, there is a well-balanced portfolio of sedans, SUV and sports cars.

PIRELLI’s tyres are divided into three product families, each with specific technical features designed to cater for precise requirements.

P Zero is the tyre family that combines PIRELLI’s experience with collaborations with the biggest car manufacturers to offer top performance every time.

The Cinturato family caters for drivers seeking tyres that have a low environmental impact, using new eco-friendly materials with lower rolling resistance that help to reduce the vehicle’s CO2 emissions.

PIRELLI Scorpion family is dedicated specifically to SUVs and crossovers, ensuring high levels of performance and safety for customers.

In the context of high-value tyres, PIRELLI is the leader in prestige tyres, with a market share of over 50% in the original equipment channel.

This is the result of solid and long-lasting partnerships with the most prestigious car manufacturers and investment in R&D was 6% of its revenues in 2021 from high-value products — one of the highest levels among the world’s major tyre producers.

STORM-ASIA: What has been the impact of sustainable and environmentally friendly practices on the brand?

FABIO MARCOLA LOPES: PIRELLI’s commitment towards sustainability has a focus on people’s lives, having a positive impact on them, caring about diversity and inclusion. It led PIRELLI to gain international acknowledgement of its commitment among the most important market indices.

One of the most recent is PIRELLI being recognised for global excellence in the Automobiles & Components sector in the Dow Jones World and Europe indices.

PIRELLI is also the first company in the world to produce a line of tyres certified by the Forest Stewardship Council designed for the new BMW X5, setting a new milestone on the path to ever more sustainable production.

Moreover, PIRELLI announced the launch of a project in the Indonesian forest of Hutan Harapan, in collaboration with the BMW Group and Birdlife International, which entails activities in support of local communities, forest conservation and protection of at-risk animal species.

PIRELLI’s commitment towards sustainability extends beyond road tyres but also in the motor sport arena where it is the only tyre maker in the world to receive 3 stars from the Environmental Accreditation Programme of FIA.

All these contribute to achieving our sustainability targets for 2025-2030.

STORM-ASIA: How has PIRELLI applied technology to its business?

FABIO MARCOLA LOPES: The main segment for PIRELLI are the high-value tyres, which means car tyres with a rim size of 18 inches and above or 17 inches and above with specialties, bearing in mind the need for sustainable mobility. So we look at tyre technologies like PIRELLI Seal Inside, PIRELLI Run Flat, PIRELLI Noise Cancelling System (PNCS).

PIRELLI Seal Inside is a self-sealing technology that allows drivers to continue driving safely without losing air from the tyre even in the event that it is pierced up to 4mm. Thus, drivers can still maintain complete control of the vehicle, without having to stop and replace a damaged tyre in unsafe conditions.

Another puncture-proof technology is the PIRELLI Run Flat, which allows drivers to keep on driving for around 80km and at a top speed of 80kmh in complete safety even during a rapid loss of inflation pressure. It is the ideal solution to ensure road safety without sacrificing driving pleasure in case of a sudden loss of pressure following a puncture.

PNCS is a technology that lowers the noise inside the vehicle, thanks to a sound-absorbing device applied to the internal circumferential wall of the tyre. It reduces noise by half and offers significantly improved driving comfort.

Another technological innovation is the PIRELLI Cyber Tyre, intelligent tyres equipped with sensors offering a plethora of information to the car and driver. These will contribute to delivering essential information to improve vehicle performance and driving safety.